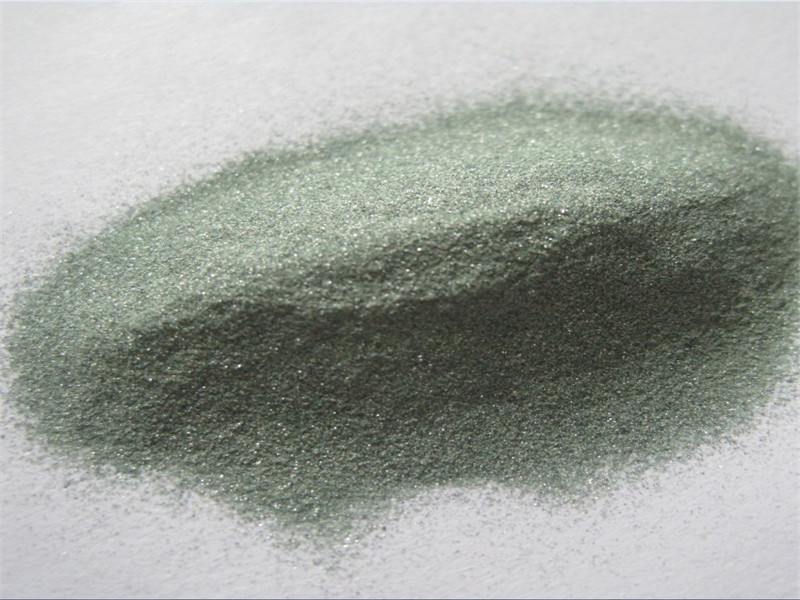

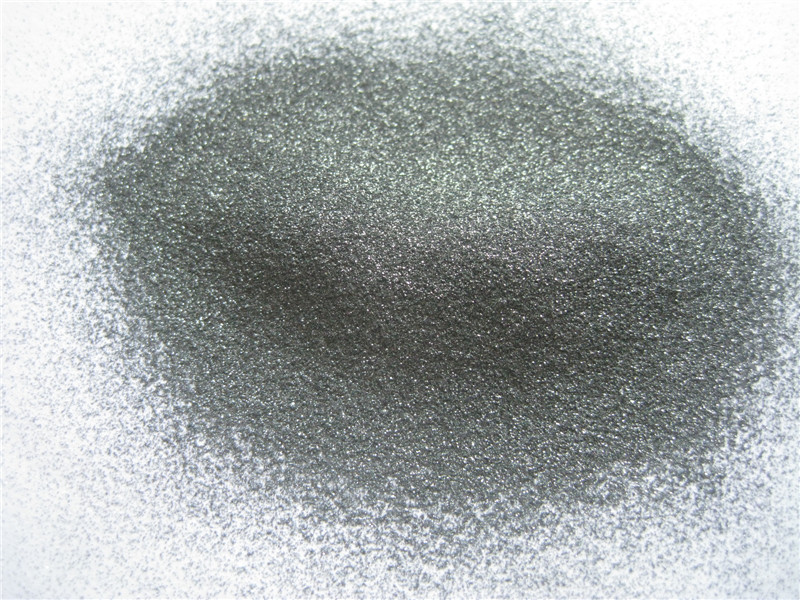

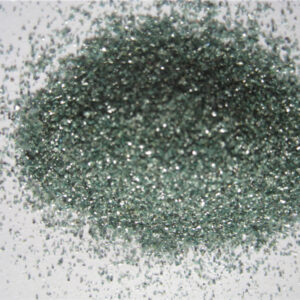

GRÜNES SILIZIUMKARBID TYPISCHE CHEMISCHE ANALYSE [%]

| So | Fe 2 O 3 | FC | F.Si | SiO 2 | RECHT |

| 99,0 | 0,10 | ≤0,20 | ≤0,20 | 0,50 | <0,05 |

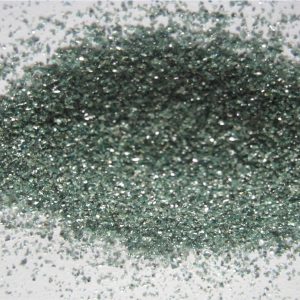

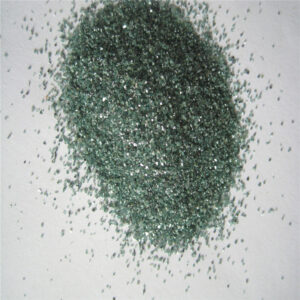

GRÜNE SILIZIUMKARBID PSD PARTIKELGRÖßENVERTEILUNG

| F008 | +4000um | 0 | +2800um | ≤20% | +2360um | ≥45% | +2360+2000um | ≥70% | -1700um | ≤3% |

| F010 | +3350um | 0 | +2360um | ≤20% | +2000um | ≥45% | +2000+1700um | ≥70% | -1400um | ≤3% |

| F012 | +2800um | 0 | +2000um | ≤20% | +1700um | ≥45% | +1700+1400um | ≥70% | -1180um | ≤3% |

| F014 | +2360um | 0 | +1700um | ≤20% | +1400um | ≥45% | +1400+1180um | ≥70% | -1000um | ≤3% |

| F016 | +2000um | 0 | +1400um | ≤20% | +1180um | ≥45% | +1180+1000um | ≥70% | -850um | ≤3% |

| F020 | +1700um | 0 | +1180um | ≤20% | +1000um | ≥45% | +1000+850um | ≥70% | -710um | ≤3% |

| F022 | +1400um | 0 | +1000um | ≤20% | +850um | ≥45% | +850+710um | ≥70% | -600um | ≤3% |

| F024 | +1180um | 0 | +850um | ≤25% | +710um | ≥45% | +710+600um | ≥65% | -500um | ≤3% |

| F030 | +1000um | 0 | +710um | ≤25% | +600um | ≥45% | +600+500um | ≥65% | -425um | ≤3% |

| F036 | +850um | 0 | +600um | ≤25% | +500um | ≥45% | +500+425um | ≥65% | -355um | ≤3% |

| F046 | +600um | 0 | +425um | ≤30% | +355um | ≥40% | 355+300um | ≥65% | -250um | ≤3% |

| F054 | +500um | 0 | +355um | ≤30% | +300um | ≥40% | +300+250um | ≥65% | -212um | ≤3% |

| F060 | +425um | 0 | +300um | ≤30% | +250um | ≥40% | 250 + 212um | ≥65% | -180um | ≤3% |

| F070 | +355um | 0 | +250um | ≤25% | + 212um | ≥40% | +212+180um | ≥65% | -150um | ≤3% |

| F080 | +300um | 0 | + 212um | ≤25% | +180um | ≥40% | +180+150um | ≥65% | -125um | ≤3% |

| F090 | +250um | 0 | +180um | ≤20% | +150um | ≥40% | +150+125um | ≥65% | -106um | ≤3% |

| F100 | + 212um | 0 | +150um | ≤20% | +125um | ≥40% | +125+106um | ≥65% | -75um | ≤3% |

| F120 | +180um | 0 | +125um | ≤20% | ≥40% | ≥40% | +106+90um | ≥65% | -63um | ≤3% |

| F150 | +150um | 0 | +106um | ≤15% | +75um | ≥40% | + 75 + 63um | ≥65% | -45um | ≤3% |

| F180 | +125um | 0 | +90um | ≤15% | +75um | * | + 75 + 63um | ≥40% | -53um | * |

| F220 | +106um | 0 | +75um | ≤15% | + 63um | * | +63+53um | ≥40% | -45um | * |

GRÜNE SILIZIUMKARBID HAUPTANWENDUNGEN:

-Gebundene Schleifmittel und beschichtete Schleifmittel

-Strahlen, Oberflächenbehandlung, Rostentfernung

-Nass- und Trockenstrahlmittel, Schleifen und Polieren usw.

-Boden-/Wandlaminate, verschleißfest

-Keramikprodukte: Keramik und Fliesen, Keramikfilterplatte, Keramikmembran usw

-Teflonlackierung etc

– Wärmeisolierendes Material

-Schleifscheiben, Topfscheiben, Schleifstein, Polierpads etc.

-Verwendet für Tiegel, Teile zum Brennen von Brennöfen, Gleitringdichtungen und Teilematerialien zur Herstellung von Halbleitern

VERPACKUNG:

| 25 kg PVC-BEUTEL | 25 KGS TASCHEN + 1 MT BIG BAG | 25KGS PVC-BEUTEL+PALETTE |